Faq

These questions and answers about industrial concrete flooring products will help you understand how to create and maintain an industrial concrete floor. Still have a question? - get in touch, we'll be pleased to help you.

SURFACE HARDENERS

What are the benefits of using a dry-shake surface hardener?

- Adding a dry-shake topping to an industrial concrete floor improves its durability and abrasion resistance. This means the floor is protected from the very start of its life, saving expensive repair costs later.

- A well-applied dry-shake also gives an exceptionally flat finish, ensuring MHE can run smoothly across the floor, thus reducing damage to vehicles.

- Adding colour to a floor not only enhances its appearance, but can reinforce a company’s branding.

- A lighter coloured dry-shake topping also gives the floor a light-reflective surface, which can reduce the lighting needs in the building, helping to save energy.

- The floor is also easier to keep clean – and indeed a well-finished floor can help staff to show the floor more respect and care, enhancing its life.

- A dry-shake can act as a fibre suppressant, reducing the protrusion of surface fibres in a fibre reinforced concrete floor.

What are the differences between the Rocland dry-shakes?

All Rocland dry-shake surface hardeners contain an aggregate; an abrasive (mineral, metal or synthetic particles); a binder (typically cement) to hold the mix together and make it workable during application; and a pigment to add colour. The differences between the dry-shakes are mainly due to the type of abrasive used. This affects the finish and behaviour of the dry-shake, and determines whether it is most suitable for a light, medium or heavy-duty application.

- Qualiroc includes graded quartz sand. Ideal for light-to-medium-duty applications, it is specially formulated to be a fibre suppressant in steel and polypropylene fibre reinforced concrete floor slabs.

- Qualidur is one of our best-known products, and is a popular choice for medium-to-heavy-duty applications. It uses hard synthetic mineral granules. Chemically inert, Qualidur is highly reliable and consistent in use, and is easy to maintain.

- Qualidur HP provides high-performance abrasion resistance for medium-duty industrial floors. It contains non-metallic aggregates which are carefully shaped to provide a hard-wearing and light-reflective finish.

- Qualitop Metal contains specially treated metal particles. Highly durable, it is used for heavy-duty environments, including heavy industry, airport hangars and automotive manufacturing.

- Qualitop Master is a medium-duty high-performance topping, for industrial and domestic floors. It uses mineral and hard synthetic aggregates. Although supplied as a powder, it should be applied only in a ‘fresh-on-fresh’ (‘wet-on-wet’) slurry form due to the size of the abrasive particles it contains. This gives a deep and consistent colour finish.

- Qualitop Millenium is designed for very heavy duty floors which will be subject to intense wheeled traffic and abrasion. It contains hard synthetic non-metallic particles, so is chemically inert and very reliable and consistent in use.

- Qualitop Titanium contains very hard metallic non-oxidising aggregates. It has excellent impact resistance and load-bearing properties, so is ideal for heavy-duty environments.

What are the benefits of a ‘wet-on-wet’ slurry topping?

Firstly, the colour finish. Blending our dry-shake into a slurry before applying it to the floor improves the colour of the finished floor – it’s a deeper and more consistent colour.

Secondly, the floor’s life. Because a slurry is applied more thickly than dry-shake, the floor’s surface is provides better protection. It is possible to achieve a lifetime of 20-25 years with a slurry surface hardener.

A slurry application requires more dry-shake, and it takes longer to apply, so it is a more expensive process – but the results are impressive and long-lasting. All our dry-shake range can be applied as a slurry (also called ‘wet-on-wet’ application); and we recommend that Qualitop Master is always applied as a slurry due to its formulation.

The video below shows a wet-on-wet surface hardener application.

How many colours of dry-shake are available?

We offer 16 standard colours – but we can make any colour you need! So, if you want a certain floor colour to match your company branding, we can create it. Get in touch with us to find out more.

What does heavy duty, medium duty, light duty mean?

By ‘duty’ we essentially what kind of traffic is likely to pass over the floor, and how much of it there will be.

Light duty means vehicles with rubber wheels; and/or less than 100 pedestrians a day.

Medium duty means vehicles with urethane and elastomer wheels; and/or 100 to 1000 pedestrians a day.

Heavy duty means steel and polyamide wheels; and/or over 1000 pedestrians a day.

These aren’t the only considerations in choosing a dry-shake surface hardener. You also need to consider what the building will be used for, as this may highlight other issues which affect how hard the floor will need to work.

How much dry-shake surface hardener do I need for my floor?

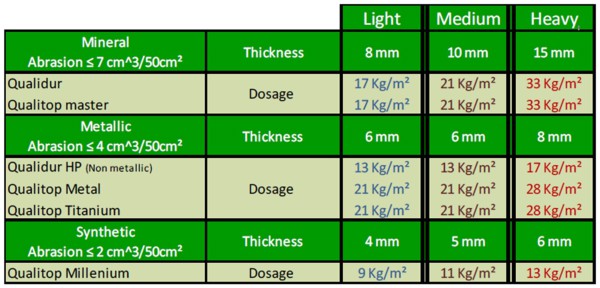

The answer depends on how hard the floor will need to work, and what impact and abrasion it is likely to receive during its lifetime. The chart below is a rough guide, and you may find our article about choosing the right dry-shake helpful. Our technical advisers will be happy to help you calculate the right dosage and choose the most appropriate product.

What’s the difference between Qualitop Millenium and Qualitop Titanium?

Both Qualitop Millenium and Qualitop Titanium surface hardeners are suitable for very heavy duty environments.

The main difference between the two is their composition. Qualitop Titanium contains small metal particles; Qualitop Millenium is a non-metallic mix, which contains very hard synthetic aggregates.

In terms of abrasion resistance both are very hard wearing, but Qualitop Millenium is superior, and in fact is our best product. When a Boehm test was conducted on Qualitop Millenium, it achieved an impressive 1.5cm3/50cm2 result (for concrete without a surface hardener the result was 9cm3/50cm2). For Qualitop Titanium the result was also very good – 3cm3/50cm2. So both will offer a dramatic improvement to a concrete floor’s abrasion resistance.

In terms of the dosage required, the two are very similar – although we recommend a slightly higher dosage for Qualitop Titanium. For a fresh-on-fresh (wet-on-wet) application the recommended dosage is the same. The amount used will depend on the level of protection required and the threats of damage to the floor during its lifetime.

Both are non-rusting, without the need to add an extra protective layer. Both have the same excellent compressive and flexural strength. Both require a curing agent to be applied. Both are available in our wide range of colours!

For further guidance on the best choice for your project, please refer to our detailed technical datasheets, or call our team for advice.

What’s the difference between Qualitop Titanium and Qualitop Metal?

Both Qualitop Titanium and Qualitop Metal are heavy duty surface hardeners containing metal particles.

The main difference between the two is their composition, and the nature of the metal they contain.

Qualitop Titanium contains metallic aggregates which are non-oxidising. This makes the floor resistant to rusting, so with a normal cleaning and maintenance regime it will maintain its smart appearance for years, without the need for an additional coating.

Qualitop Metal contains a ductile, oxidising metal wool, but no aggregates. The nature of the metal gives this product spark-resistant properties, so it is suitable for where an anti-static floor is needed, such as in electronics manufacturing, or where gas or solvents are handled. To help maintain its appearance it is best used internally, and in dry environments.

Both are very hard-wearing abrasion resistant surface hardeners (Taber abrasion tests indicate Qualitop Titanium is slightly superior). Both have equally good compressive and flexural strength. For dry-shake (dry-on-wet) application, the dosage rate will be similar for both: it will be slightly higher for Qualitop Metal in a wet-on-wet (fresh-on-fresh) application.

Please download the technical datasheets from the product pages for more information, or speak to our technical staff if you need further guidance.

What’s the difference between Qualidur and Qualidur HP?

As its name suggests, Qualidur HP (High Performance) is an advanced formulation of Qualidur. It contains all of Qualidur’s benefits, and more, but the mineral composition is harder, and the result is a better wearing surface.

In terms of its abrasion resistance, Qualidur HP is excellent, and is actually closer in performance to our metallic dry-shake Qualitop Titanium.

Qualidur HP has better compressive and flexural strength than Qualidur too; and only slightly less than Qualitop Titanium.

It also has anti-static properties.

So if you are seeking a good non-metallic surface hardener for logistics, distribution centres, food processing plants and workshops, Qualidur HP is a great choice.

Please talk to our technical team if you would like specific advice for your application. We can help you calculate the cost-effectiveness of our various products and help you make the right choice.

What causes efflorescence and how do you remove it?

POLYMER SCREEDS

What is a concrete floor screed, and why should it be used?

A floor screed is a concrete floor coating, comprising cement, aggregates and admixtures. Adding a screed provides a fine surface finish to a concrete slab, and can add colour too.

Indurit is our range of self-levelling screeds. There are products suitable for application in different thicknesses, for decorative concrete, and for the food industry. Please browse our range, and ask us if you have any questions about the right screed for your project.

Please note, a screed will provide a neat and smooth finish, but it will not offer the same long-term floor protection as our surface hardeners.

How should I choose the right screed from the Indurit range?

We hope the suggestions below will help you. Please refer to each product page for specific usage guidance – and ask if you still have questions.

Internal use: All our screeds

External use: Indurit, Indurit Spray, Indurit Topping

Thin screeds, up to 4mm: Indurit Spray, Indurit Topping

Screed 4mm – 15mm: Indurit, Indurit Flow

Screed over 15mm: Indurit Mortar

Screed over 20mm: Indurit Screed, Indurit Mortar

Food manufacturing: Indurit, Indurit Flow

Acid/oil resistance: Indurit

Decorative: Indurit Spray, Indurit Topping

Walls: Indurit Spray, Indurit Topping

FIBRES

What’s the difference between polypropylene and steel fibres?

Polypropylene (PP) fibres for concrete are very thin, strong, synthetic strands. Once they are mixed into the concrete they are almost invisible. Their main function is to control the early shrinkage in the concrete slab while it cures. They reduce the amount of water which bleeds out of the concrete, as rapid evaporation can result in cracking. Visit our PP fibre page for Proroc NT to learn more.

Steel fibres are a much thicker and much more obvious addition to a concrete floor. Their function is to build in strength, and so are usually used instead of traditional steel reinforcing mesh. They also contribute to shrinkage control, and increase the load-bearing capacity of the slab. It’s usual to cover the surface of a steel fibre reinforced concrete (SFRC) floor with a surface hardener, which also suppresses the fibres near the surface. Our steel fibres are Eurosteel 50-100 and IVX 50.

CURING AND SEALING

What is the benefit of using a concrete floor sealer?

It’s important to use a floor sealer on a newly-laid concrete floor to control the evaporation of the water in the slab. Without a sealer, the water near the surface of the slab will evaporate more quickly than the water within the slab, and this can cause cracking. A sealer ensures that the slab cures evenly, helping to give a strong and durable floor.

Browse our range of concrete curing and sealing products

Which curing and sealing agent should I choose?

Here is a quick overview of our range of curing and sealing compounds for concrete floors. Please browse to the relevant pages for more details. If you have any specific questions about product suitability, please contact our team for advice.

New concrete floors: all products

To revive older concrete floors: Roc Seal

External use: Roc Seal Premium, Roc Release Agent, Ecocure 17

Concrete curing and sealing combined: Roc Seal Premium, Roc Seal

Concrete curing only: Ecocure 17, Roc Cure

Sealing only: Roc Seal Premium, Roc Seal

For stencilled concrete floors: Roc Release Agent

For self-compacting concrete floors: Ecocure 17

Water-based formula: Ecocure 17

ADMIXTURES

Can a water-reducing admixture be used with a dry-shake surface hardener?

A dry-shake surface hardener needs to be mixed with bleed water from the fresh concrete to achieve the correct consistency and adhere properly to the slab. If the water in the concrete is reduced, there may not be enough bleed water to allow the dry-shake to be properly worked in. If you are intending to use a dry-shake, you must first discuss this with your concrete supplier or consultant concrete engineer. An alternative option is to apply the surface hardener as a wet-on-wet slurry, because this is a completely separate mix which is not reliant on bleed water.

Can more than one admixture be used in a concrete mix?

Yes, some admixtures can be used together. For example, Roc PO Fluid (for workability) can be used in conjunction with Roc NC Acclerator (for reduced curing time). But only one type of water-reducing superplasticiser can be used in a mix – so choose either Roc PO Fluid, Roc Fluid, or Roc MA Fluid.

Roc HP can be used with Roc NC Accelerator.

We recommend you discuss the exact properties of your concrete mix with your concrete supplier or consultant concrete engineer.

Is a curing and sealing agent still required if a water-reducing admixture has been used?

Yes. The admixture will modify the amount of water in the freshly-poured slab, but it is still important to control water evaporation during the curing process. The slab still needs to cure consistently, so it is still important to follow good curing and sealing practice.

Which admixture should I choose?

Here is a quick guide to the main properties of our admixtures. Please refer to each product page for full details, or contact us if you have questions about product suitability for your application.

Water reducing admixtures: Roc MA Fluid; Roc Fluid; Roc PO Fluid

Reduced curing time: Roc NC Accelerator

Improved workability: Roc MA Fluid, Roc Fluid, Roc PO Fluid

Waterproofing: Roc HP, Roc PO Fluid

Oil, fuel and mineral resistance: Roc HP

JOINT SEALING

Why should I seal a joint in a concrete floor?

Once people and vehicles begin to use a building and move across the floor joints, the joint edges (arrises) will be vulnerable to damage. Sealing a joint adds support to the arrises, protecting them from the chips and spalling caused by impact on the joint.

Sealing a joint also stops debris and contaminants entering the joint. It also stops chemicals from seeping into the ground. Where the floor is mainly used by pedestrians, a joint sealant can prevent heels from catching in the joint.

Browse our range of joint sealants.

When should I seal a joint in a concrete floor?

Joints are vulnerable from the moment they are first cut; so we recommend sealing newly-cut joints using either Roc Plast 55 or Roc joint PU920/925.

However, as the concrete floor slab cures the joints will open further, and the initial sealant may well pull away from the sides of the joint. So once the joint has opened fully we recommend removing the initial sealant and re-sealing the joint with a permanent sealant, appropriate for the joint width.

Which joint sealant should I choose?

Here is a quick overview of our range. Please browse to each page for more information, and contact us if you have any questions about product choice.

For new saw-cut joints: Roc joint PU920/925, Roc Ethafoam, Roc Plast 55

For older saw-cut joints, one month old or more: Roc joint PU12, Roc joint PU920/925, Roc Ethafoam

For immediate use: Roc Plast 55

For joints up to 6mm: Roc Plast 55, Roc joint PU12, Roc joint PU920/925, Roc Ethafoam

For joints from 7 to 16mm: Roc joint PU12, Roc Ethafoam

For joints over 16mm: Roc joint PU12

For external use: Roc joint PU12, Roc joint PU920/925, Roc Ethafoam

BONDING AGENTS FOR CONCRETE

When should a concrete bonding agent be used?

You must use a concrete bonding agent every time you place new concrete on top of existing concrete – eg, when repairing damaged concrete, or adding a fresh surface to a slab. It is essential to use a bonding agent, otherwise the two layers will not join, and you will be left with weak concrete, prone to spalling.

What are the differences between Rocland bonding agents?

The choice depends on the strength of adhesion needed, the composition of the new top layer of concrete, and whether the bonding agent needs to provide a moisture barrier.

- For our strongest adhesion: Cemcol

- For use with hard aggregate screeds: Cemcol

- For use with mortar: Roc Latex

- For masonry joint repairs: Roc Latex

- To create a moisture barrier between layers: Roc Prim

Are Rocland bonding agents supplied ready to use?

CONCRETE RESOURCES

Where can I learn more about concrete floors?

Here are some of the most useful resources we have found:

ACIFC: The Association of Concrete Industrial Flooring Contractors

TR34, 4th edition – link to the Concrete Bookshop to purchase

Eurocode 2: Design of concrete structures

Common abbreviations for concrete-related products

British Ready Mixed Concrete Association – technical articles and guides

DOWNLOADS

![]() Slip resistance 1

Slip resistance 1

![]() Slip resistance 2

Slip resistance 2

![]() Preventing slips and trips at work

Preventing slips and trips at work

![]() FAQ Superflat Floor

FAQ Superflat Floor

![]() Delamination of concrete floor

Delamination of concrete floor

NBS specification